Drop Forging - Open dieContents

Open die drop forging gets its name from the fact that dies on impact do not completely cover the work piece allowing the work to deform into open space. This is why an operator must position the work piece before each strike of the tool, it’s not unusual for the tool to strike a work piece many times before shaping is complete.

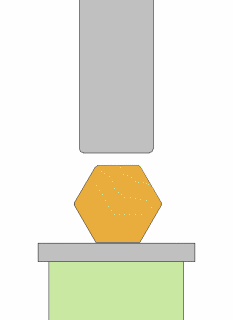

The above image "Fig 1" is showing notching, this process uses a tool similar in shape to a chisel, the operator will rotate the work piece through a gradual 360° ensuring the tool leaves an even impression around the circumference of the work piece. The operator may have to rotate the work piece several times to achieve the desired shape. For "Fig 2" multiple sided shapes can be made with much the same method as notching, just with different tools, for shapes where more accuracy is required for example the six sided shape above a machine jaw might be used to hold the work piece in place and move it through a consistent rotation of degrees each tool impact. Open die drop forging is capable of producing forgings from around 2kg to 150 tons and when a very large structurally sound part is required open die forging is usually top choice. |